Metal forming at the highest level

Innovative punching technology

Fully automatic assembly of components

FSM Stamping - Partnership that shapes

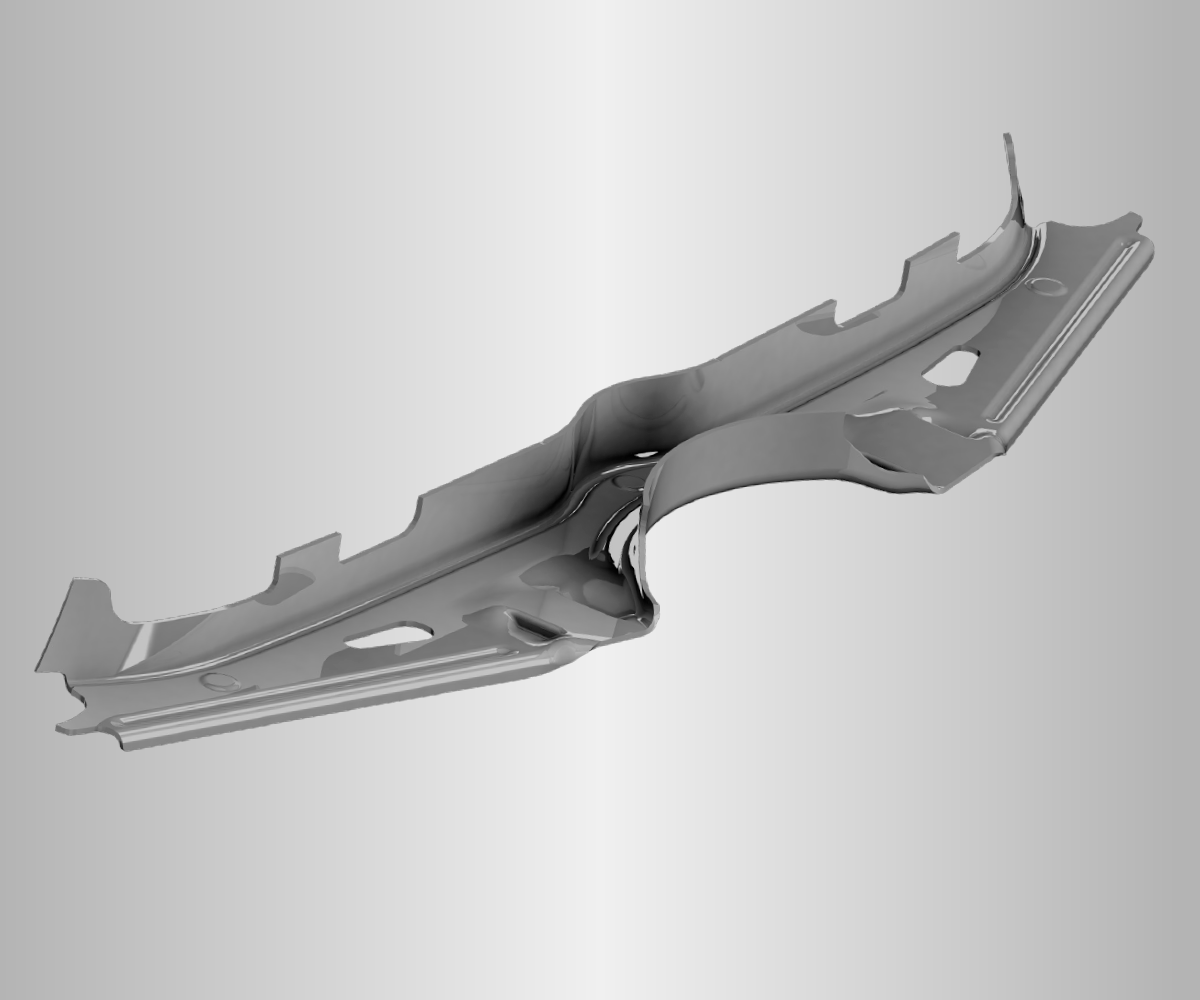

FSM Stamping manufactures sophisticated precision components for the automotive and household appliance industries as well as for railroad technology. From the safety part to the system assembly, we guarantee the fulfillment of complex customer requirements.

FSM combines more than 80 years of experience of FSM Syscomp GmbH and FSM Motec GmbH in the large-scale production of stamped and formed parts and the required tooling and automation technology.

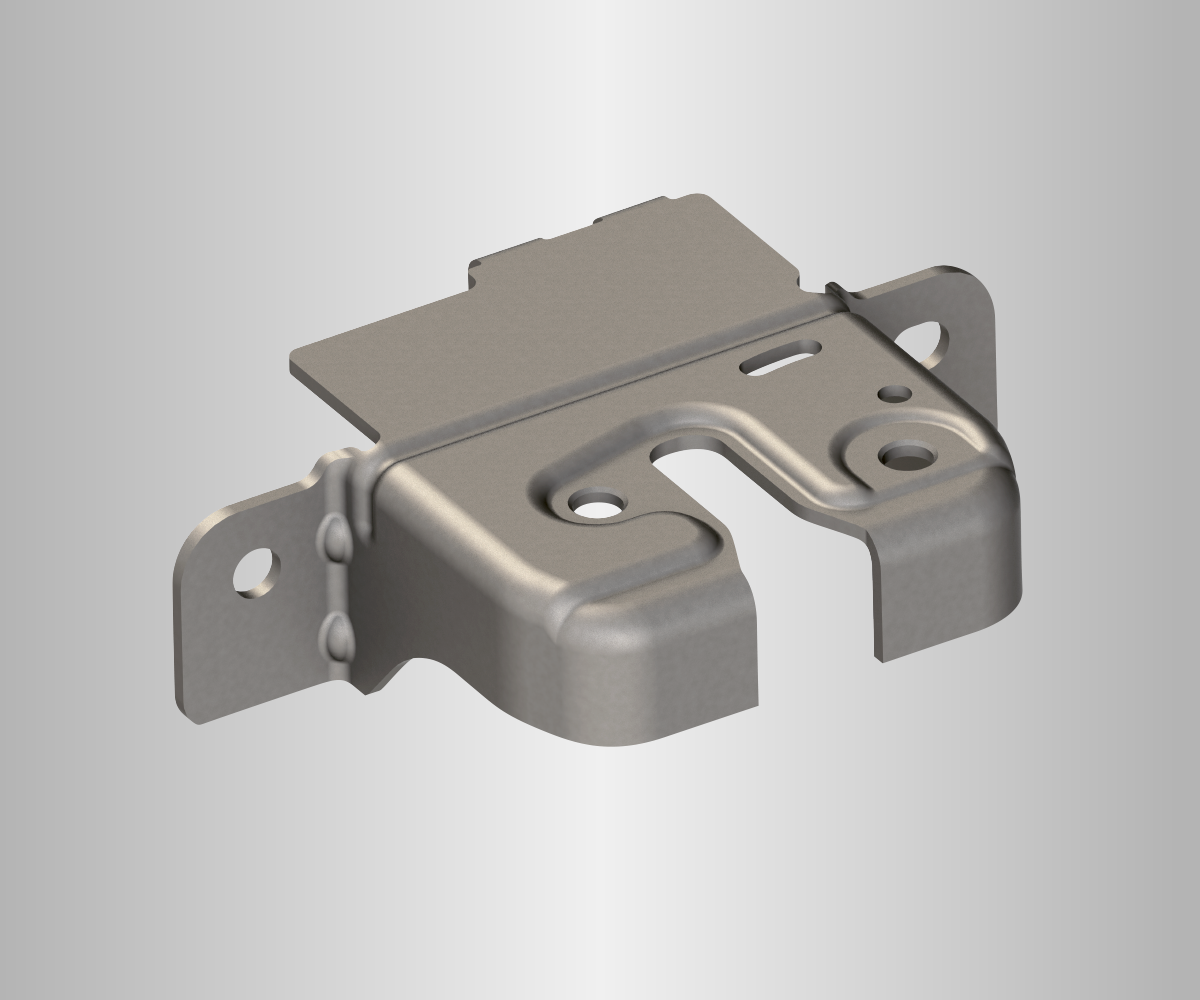

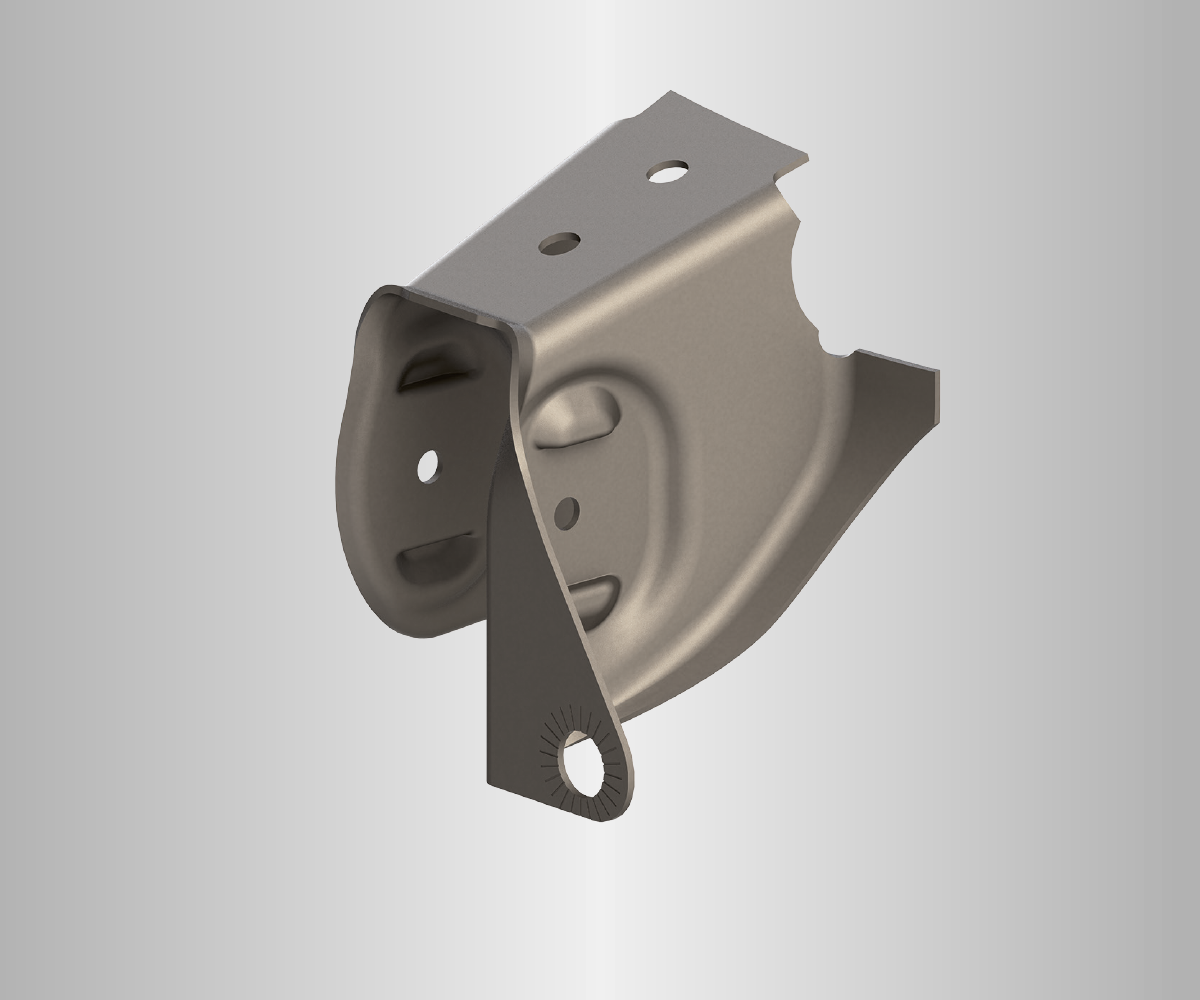

Automotive

- Body structures

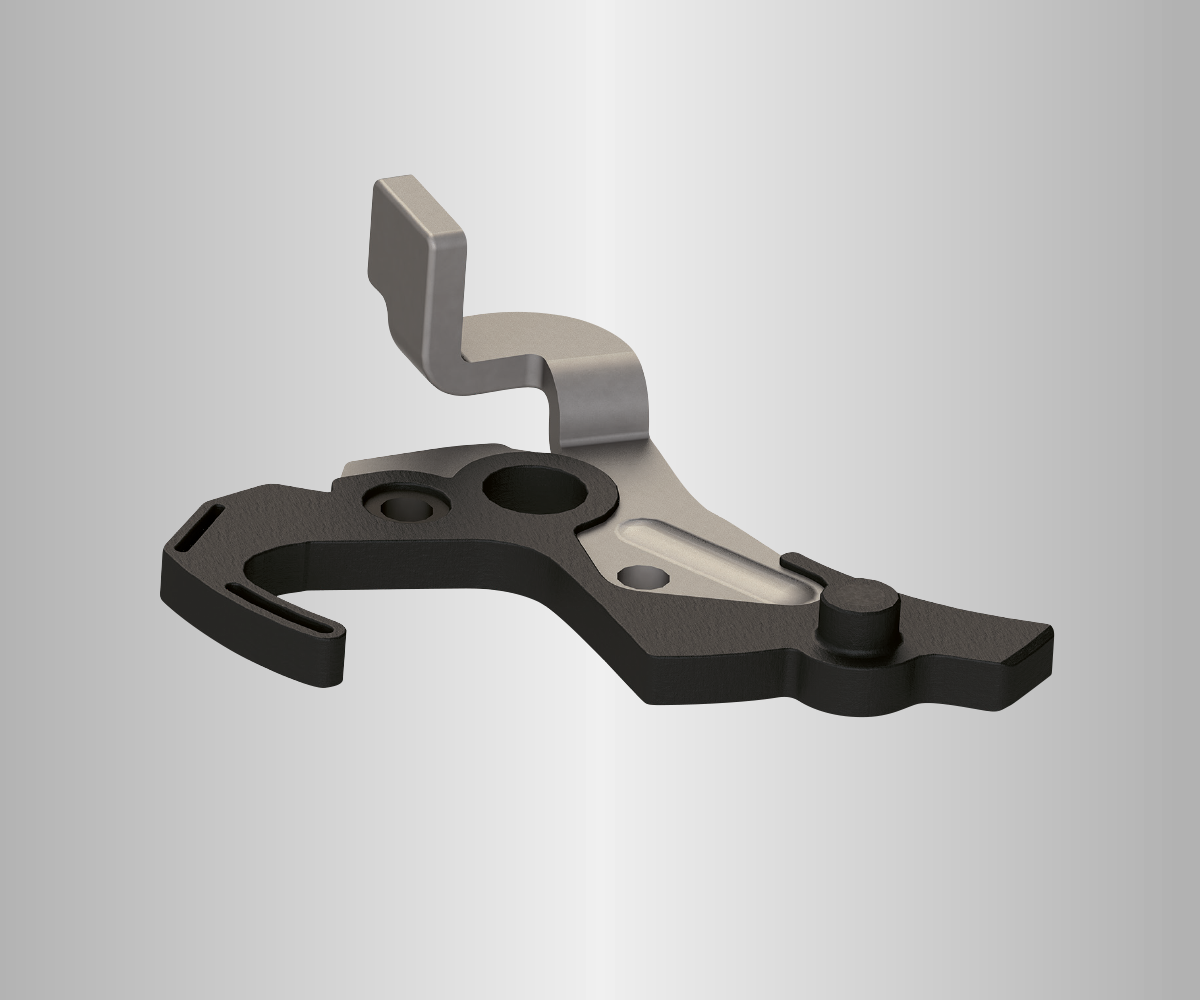

- Locking systems

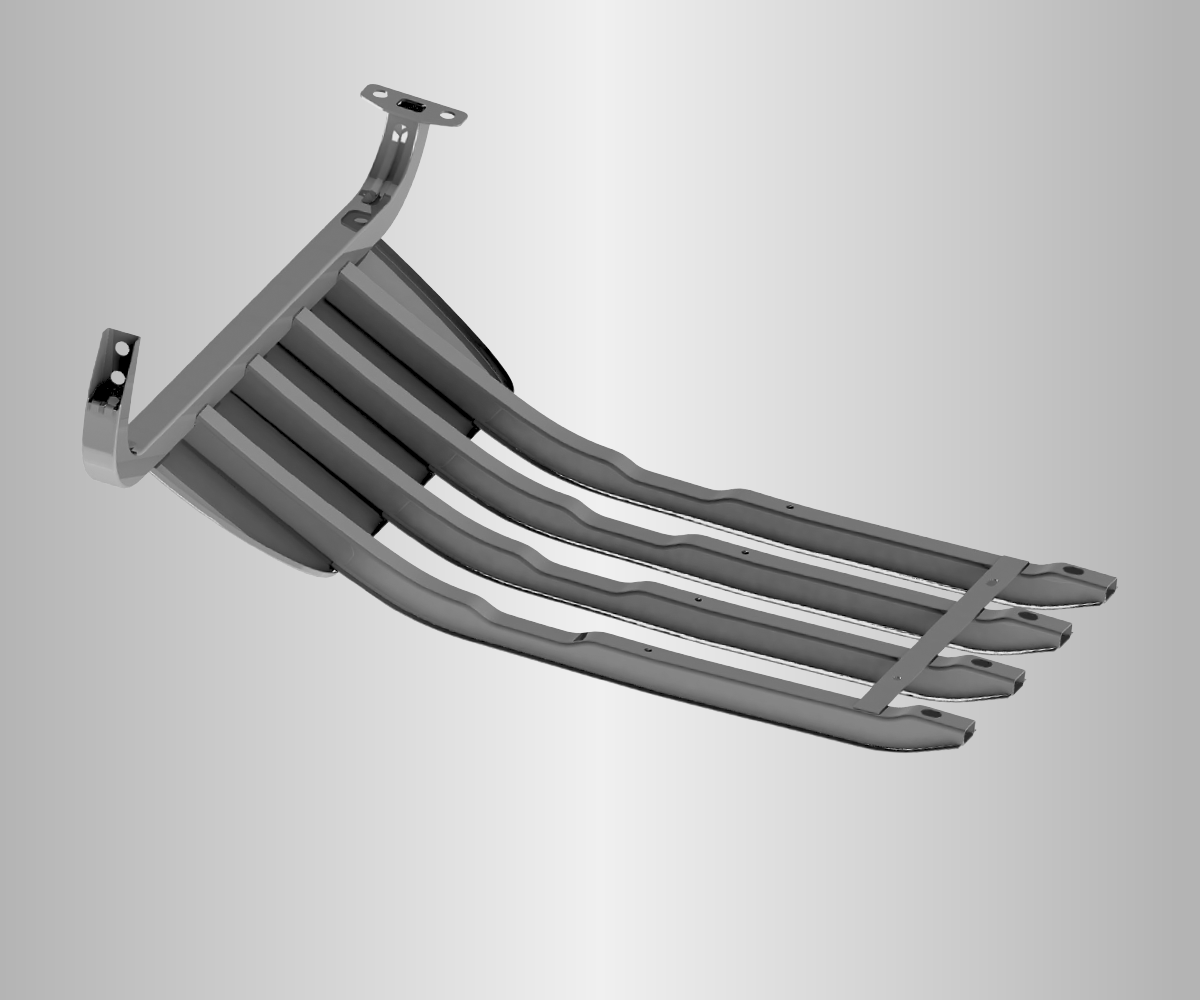

- Seat structures

Home Appliances

- Housing

- Stainless steel components

- Drum bearing

Railroad technology

- Anchoring elements in railroad sleepers

- High strength formed parts

up to 10 mm thickness

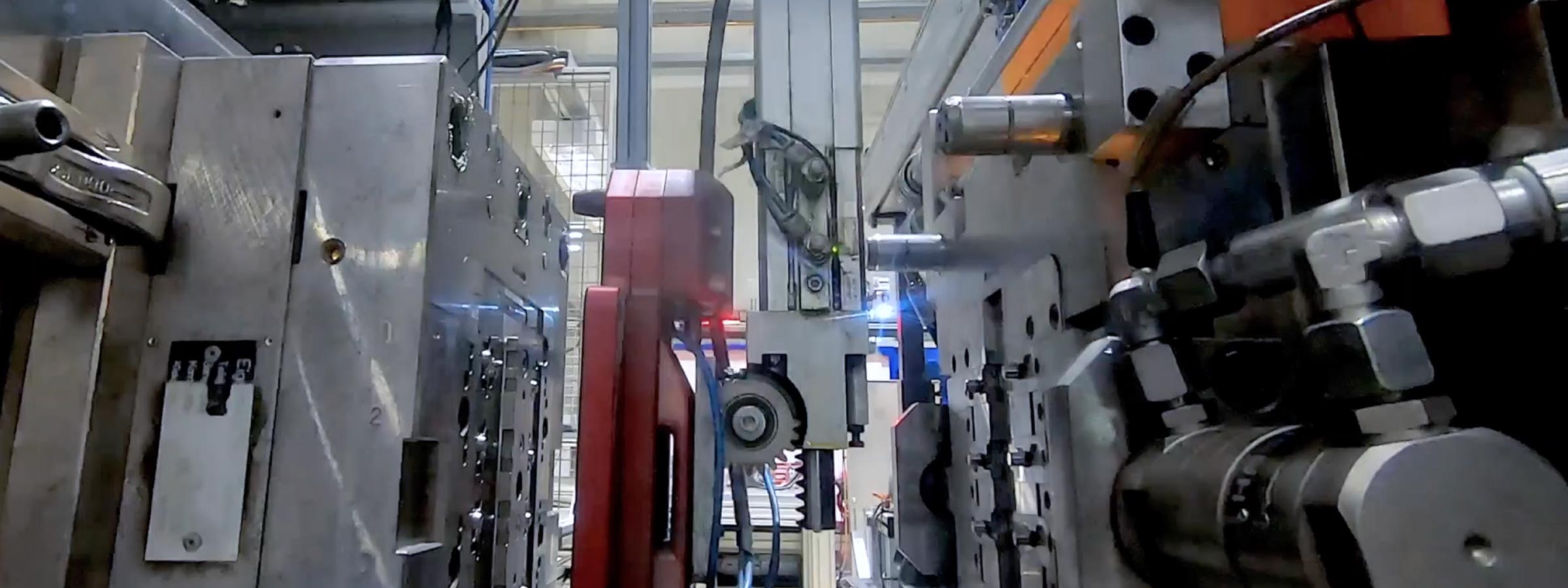

Metal forming

Progressive dies and transfer dies weighing up to 25 t are used in our press shops. Automatic punching presses with a press force of 300 to 16,000 kN and a table size of up to 5,200 × 2,300 mm are available.

- Construction consulting of the customer

- Sample and prototype construction

- Tool development and toolmaking

- Material thicknesses 0.5 – 10 mm

- Monitored forming and tapping processes

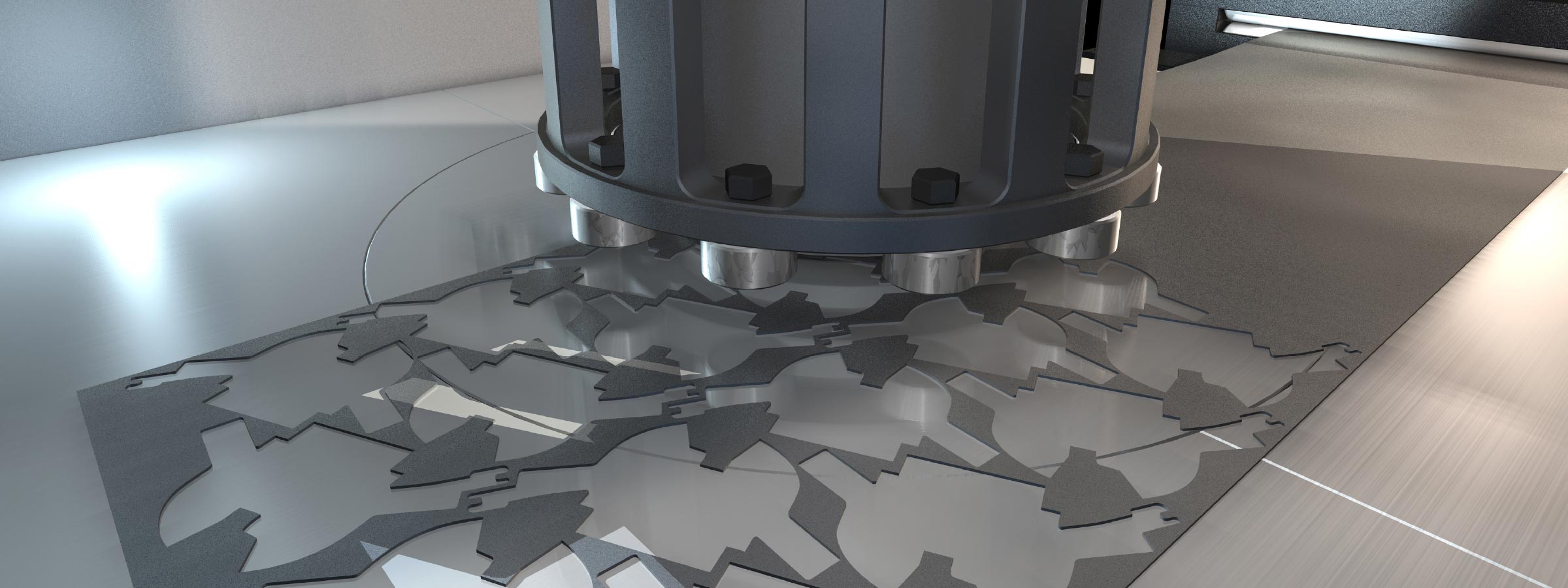

Punching technology

We develop our own stamping technologies with optimized material utilization. The patented material-saving nesting process is used on several interlinked lines.

State-of-the-art servo technology guarantees processes that are optimally matched to the component.

- Use of mother coils up to 30t weight and 1.8m width

- Improvement of the Material utilization of up to 30% possible

- 100% controls in the die cutting process

- direct transfer of the blanks to the transfer forming tool (single or multiple drop)

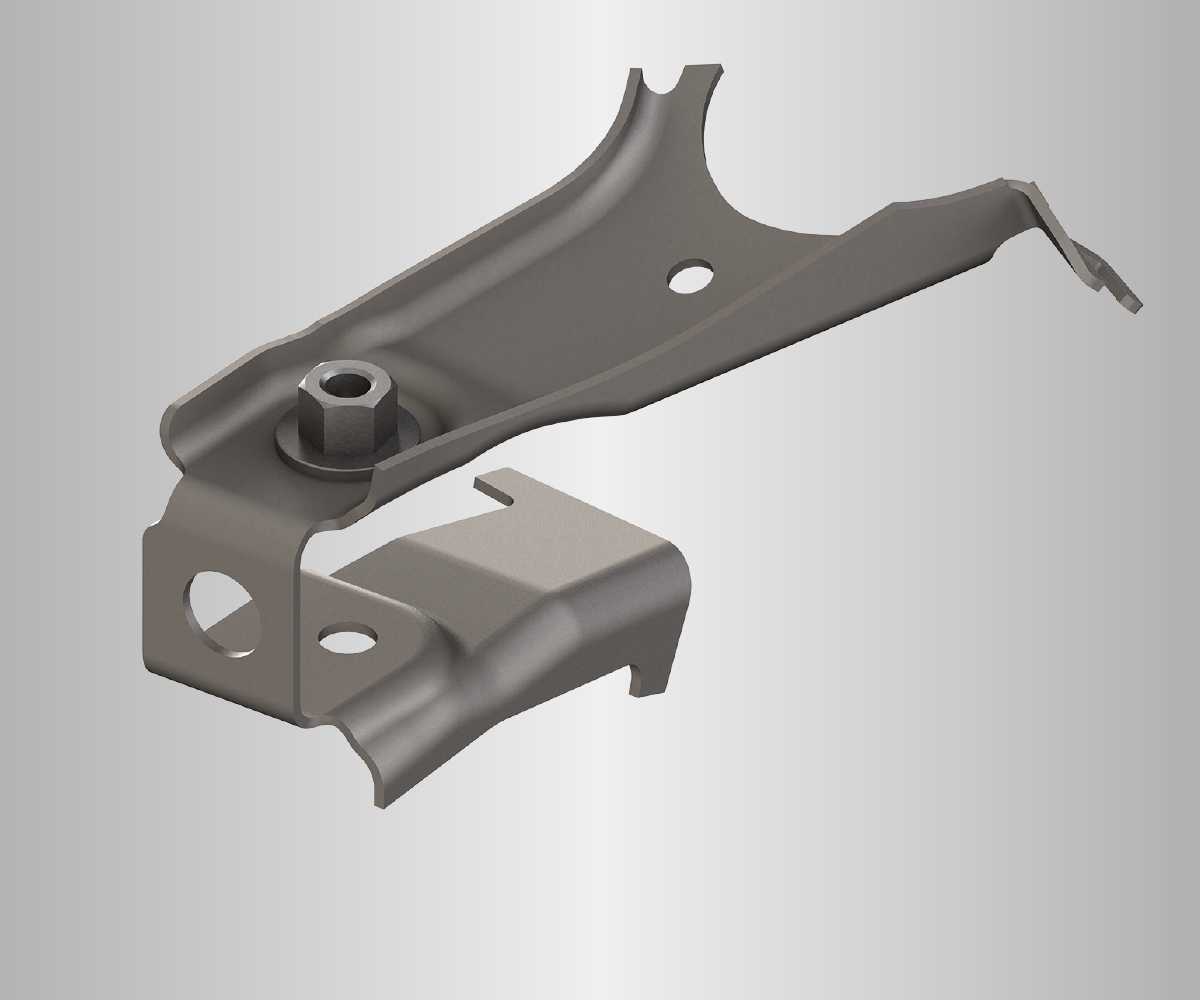

Assembly of components

The production of system components ranges from plastic-coated stampings to finished assemblies. Networked, automated manufacturing systems produce components precisely and economically, even in high volumes. Welding robots and automatic assembly machines manufacture subassemblies.

- Vibratory finishing and degreasing work tailored to the components and materials

- Rivet, tox and clinch assemblies

- MAG welding assemblies manufactured with 6-axis welding robots

- fully automatic application of sealing foams on formed parts

- unmanned hybrid part production with image processing, robot handling and 100% quality inspection

Maximum quality with system

Quality management: IATF 16949 / DIN EN ISO 9001

Environmental management: DIN EN ISO 14001

Energy management: DIN EN ISO 50001

Information security: TISAX